CORE

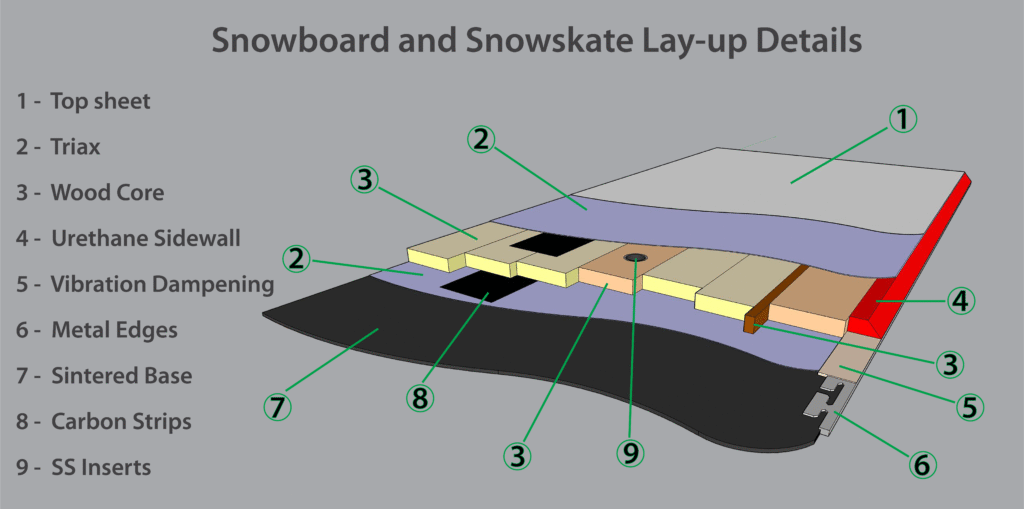

Making a good snowboard or snowskate starts with the wood core.

All our snowboards and snowskates have a full length wood core, tip to tail.

We use a combination of the best timber species that will make for a light weight, yet strong and springy core.

We use a few different wood species, Paulownia, poplar, beech and bamboo.

They are used in different ratios to customise the core for the rider and intended use.

BASE

We have two types of base material we use. We source our base from ISO Sports in Austria.

We have a clear sintered base ISO 7500, or what we mostly use is the high carbon sintered black race base ISO 7510.

EDGES

Hardened and tempered fine steel profiles.

We full wrap all our snowboards and snowskate models apart from our two snowskate fish tail shapes.

SIDEWALLS

VIBRATION DAMPENING

FIBERGLASS

We use a few different types and weights of fiberglass in our lay-ups

Typical is a layer of 18 or 22oz TRIAX glass.

We then may use various strips of carbon reinforcing placed in varying positions and varying widths.

We may also use other types of “glass” such as Basalt for vibration dampening, or a vector netting an aramid weave.

Our aim on many boards we make is to have glass clear top sheet, using colour tints in the epoxy resin to show through to the wood core. With these types of top finishes we use a number of 6oz flat weave glass layers that will “clear out”, unlike the industrial triax’s, we are then able to apply our screen printed rice paper logos down, then lay a very thin 2oz final layer of glass over. We apply an epoxy filler coat, sand back and spray a 2 pack clear gloss over.